Power Grid technical services

POWER GRID TECHNICAL SERVICES is engaged in Manufacture and Hiring of Smart Drying System(Low Frequency Heating Equipment) for power transformers and reactors of any capacity and any voltage class. The equipment can heat any transformer wingdings above 100 degrees centigrade at site.

Preface

Ingress of moisture in the transformer will lead to reduction of IR values & ultimately result in failure of the transformer. In case of distribution transformer they can be immediately replaced & repairs undertaken en mass. For power transformer it is a laborious exercise to remove the moisture from the insulation & windings. Many a time the transformer has to be brought to the repair bay of the utility thus involving much labour, time & money.

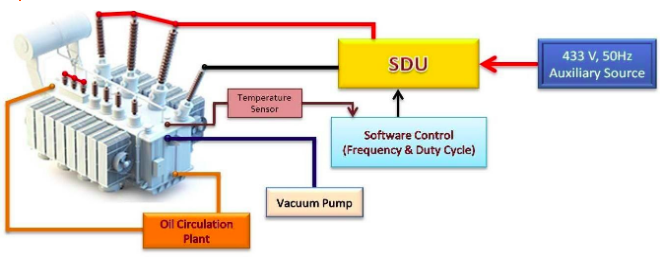

This equipment can be used in association with the conventional hot oil circulation and vacuum method. It will monitor the temperature & drying , making the optimum use of hot oil & vacuum process. This has been used both at repair unit & on site. The system is very useful for all State & Central Power utilities apart from generation stations. The details of the system are explained below.

In conclusion this is an innovative method in drying of transformers in a cost effective way at a lesser time. As this uses low voltage high current application the power required for the operation is considerably less.

Smart Drying System for Transformers and Reactors

New concept over conventional methods….

- Effectively removing the moisture from the cellulose insulation is a key process at the transformer manufacturing unit and site. The quality of the drying of the insulating material is critical in meeting dielectric requirements and assuring trouble-free service for users.

- Smart Drying Unit works on the principle of modified low voltage high current power (at low frequency) feeding to the parallel windings, which is a state-of-the-art process of drying transformer insulation by supplying a controlled, temperature monitored system.

- The system is faster and better than conventional hot oil and vacuum drying methods, it cuts energy costs by as much as half, and speeds up the dying process.

SINGLE PHASE SMART DRYING SYSTEM (500AMPS)

Overview

- Virtually all moisture in a transformer is in the fixed insulations, i.e insulation paper and press boards.

- Humidity of 3-4% may increase the degradation rate of paper by a factor 10 or more, compared to dry paper.

- Therefore it is important to access moisture in the insulation system and maintain within permissible limits.

- The most effective way of drying the transformer insulation is by heating and vacuum simultaneously (as it is done during vapor phase drying).

- Heating of windings and insulation is done by “Modified Low Voltage High Current Power” and applying a vacuum to the transformer tank at the same time.

- In order to prevent hot spots during drying the applied current for heating should be monitored as per schedule. Consequently the copper loses and the risk of potential hot spots at points with higher resistance will be negligible.

LIST OF TRANSFORMER DRIED AND COMMISSIONED USING L F H (SMART DRYING SYSTEM )

- 55 MVA 220/110/11KV CGL MAKE POWER TRANSFORMER at 220 KV KPTCL substation Else (Sirsi – KARNATAKA)

- 8 MVA 66/11KV ANDREW YULE MAKE POWER TRANSFORMER at 66KV KPTCL substation Hettur ( Sakleshpur – KARNATAKA)

- 10 MVA 110/11KV EMCO MAKE POWER TRANSFORMER ,SL NO HT1710/12640 at KPTCL repair unit HUBBALLI ( KARNATAKA)

- 10 MVA 110/11KV VOLTAMP MAKE POWER TRANSFORMER ,SL NO JN8097/3 at KPTCL repair unit HUBBALLI ( KARNATAKA)

- 10 MVA 110/11KV VOLTAMP MAKE POWER TRANSFORMER ,SL NO JN8097/6 at KPTCL repair unit HUBBALLI

- 20 MVA 110/33-11KV INDOTECH MAKE POWER TRANSFORMER ,SL NO IT37437 at KPTCL repair unit HUBBALLI

- 20 MVA 110/33-11KV NGEF MAKE POWER TRANSFORMER ,SL NO 2800060072 at KPTCL repair unit HUBBALLI

- 10 MVA 110/11KV INDOTECH MAKE POWER TRANSFORMER ,SL NO IT34717 at KPTCL repair unit HUBBALLI

- 50 MVA 132/33KV CGL MAKE POWER TRANSFORMER, at KK RAO ENGG WORKS Hyderabad

- 40 MVA 220/11KV ABB MAKE POWER TRANSFORMER, SL NO 12080-006 at 220 KV switch yard (pump house 1) Bettadataverakere of Upper Bhadra LIS project (Tarikere).

- 40 MVA 220/11KV ABB MAKE POWER TRANSFORMER, SL NO 12080-005 at 220 KV switch yard (pump house 2) Shantipura of Upper Bhadra LIS project (Tarikere).

- 10 MVA 110/11KV ANDREW YULE MAKE POWER TRANSFORMER, SL NO 3643/2 at M/S ANDREW YULE TRANSFORMER DIVISION, CHENNAI ( TANDELTA VALUES IMPROVEMENT)

- 20 MVA 110/33-11KV VOLTAMP MAKE POWER TRANSFORMER, SL NO JN 8031/2 AT K P T C L REPAIR BAY HUBBALLI ( DRYING AFTER REPAIRS)

- 5 MVA 33/11 KV KPRS make new power transformer No 1 @ KPRS factory Bangalore

- 5 MVA 33/11 KV KPRS make new power transformer No 2 @ KPRS factory Bangalore

- 10 MVA 110/11KV Voltamp make Power Transformer @ KPTCL repair bay Shimogga

- 67 MVA 220/11 KV EMCO make Power Transformer @ Almatti Dam Power House

- 130 MVA 220/11KV TELK make Power Transformer @ Varahi under ground Power House

Objectives

- To heat both low and high voltage windings, Modified low voltage high current power is applied to the transformer.

- Smart Drying System along with hot oil spray the whole transformer is heated uniformly and effectively. The SDS system heats the winding from inside and the hot oil spray supports the heating process by heating the outer parts of the insulation system.

System Advantages

- Minimum depolymerisation- drying of insulation.

- Up to 40% lower energy consumption.

- Minimum 50% shorter drying process time.

- Higher and accurate moisture reduction.

- No air flushing necessary to avoid corrosion.

The SDS offers a mobile alternative.

An SDS Unit with control system and accessories can be transportated to a site easily. Heating and drying the transformer can be done with hot oil spray or with conventional hot oil circulation. The combination of hot oil spray and SDS allows much higher winding temperatures, and reduce drying time compared to conventional drying methods significantly, while achieving moisture values below 1 percent.

System requirements for SDS.

Up to 100 MVA capacity power transformer

- 3phase 433V, 100 KVA auxiliary supply is sufficient.

100MVA and above up to 315 MVA capacity power transformer.

- 3phase 433V, 250 KVA capacity auxiliary supply is sufficient.

315 MVA and above power transformer.

- 3phase 433V, 500 KVA capacity auxiliary supply is sufficient.

Advantages of SDS

- Small size, less weight and compact design which is easy to carry.

- Robust & smart winding temperature monitoring system, to maintain the temperature at set temperature value.

- LCD display to observe, Status, temperature, other parameters with Hazard & operation alarms.

- Wireless connectivity for monitoring and control through Smartphone.

- Suitable for regular Drying of New power and distribution transformers at manufacturing unit.

Please click below link for video. Smart drying of 40 mva 220/11kv ABB Make power transformer at upper Bhadra project @ Tarikere, please click here

Please click below link for video. Smart drying of 10 mva 110/33_11kv Emco make power transformer at KPTCL repair bay Hubballi, please click here

POWER GRID TECHNICAL SERVICES

P. SRINIVASALU

NO 27 , MALLIKARJUN NAGAR

BEHIND KERALA SAMAJ

KUSUGAL ROAD

KESHWAPUR

HUBBALLI 580020

KARNATAKA

INDIA